In the engineering world, new technologies are constantly being developed. An example of a new design for concrete embed plates is the patented EM-BOLT Boltable Concrete Embed Plate (PATENT No.: US 9,359,756,B2). The EM-BOLT BEP-2 two-row boltable concrete embed plate model was tested at the Advanced Structures and Composites Center at the University of Maine, Orono Maine, in 2016 to determine the governing failure mode and maximum load.

Three configurations were tested: Plain concrete with A325 bolts with threads included in shear plane (A325 N), plain concrete with ASME Grade 8 bolts with threads included in shear plane (Gr. 8 N), reinforced concrete with ASTM A490 bolts with threads excluded from shear plane (A490 X). The testing procedures followed specific codes including: International Code Council – Evaluation Services Acceptance Criteria for Headed Cast-In Specialty Inserts in Concrete, ICC-ES AC446 1 test number 3, shear test in plain concrete using ASTM E448 Standard Test Methods for Strength of Anchors in Concrete Elements 2 as the test standard basis.

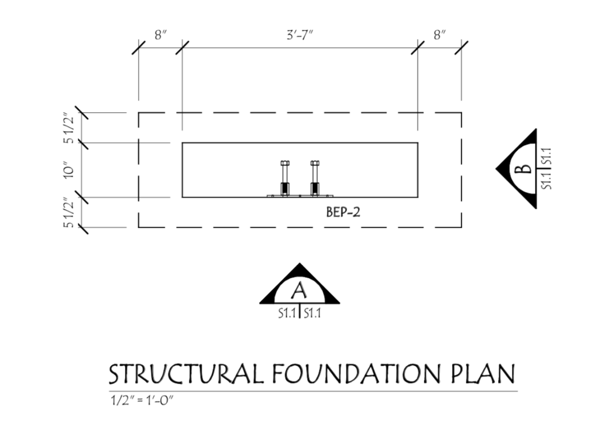

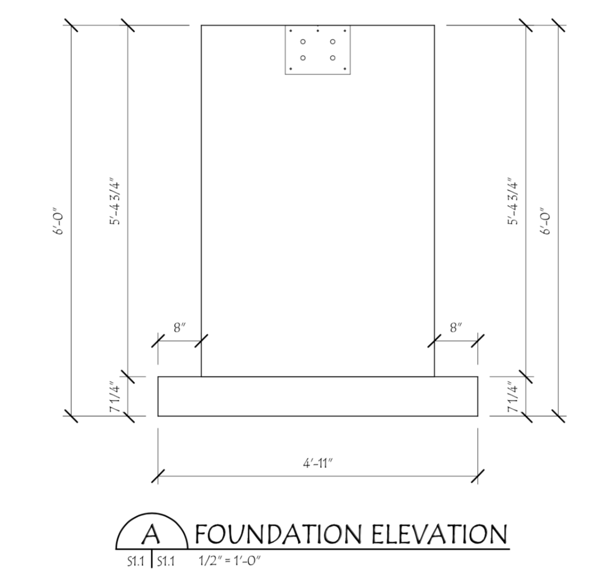

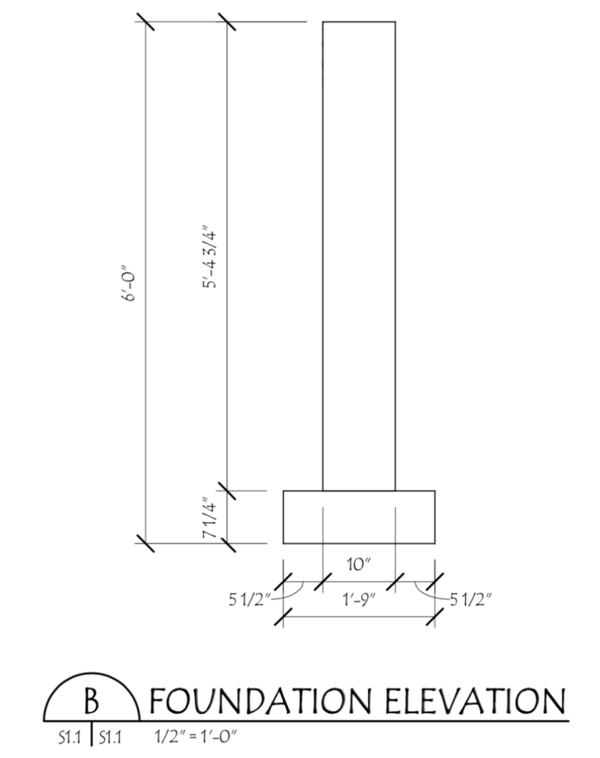

Below are the dimensions for the testing procedures of the BEP-2 concrete embed plate in concrete. Included are the structural foundation plans, and the elevation of the foundation from the front and side.

Figure 1: The Structural Foundation Plans, Top View

Concrete Embed Plate - Structural Load Test to ACI 318-14

Figure 2: The Foundation Elevation of Testing Procedures Front View

Concrete Embed Plate - Structural Load Test to ACI 318-14

Figure 3: The Foundation Elevation of Testing Procedures Side View

Concrete Embed Plate - Structural Load Test to ACI 318-14

The general design method used for BEP-2 is ACI 318-14, the anchor recommended for use is the ¾” Hex Bolt, F1554 Gr. 36, and the base material is made up of normal weight (4,000PSI) concrete. After testing, the failure modes were determined. Four failure modes were observed including bolt shear, concrete breakout combined with side-face blowout, coupler nut failures at the joint between embedded bolt and attaching bolt, and concrete breakout combined with side-face blowout and coupler nut failures at the joint between embedded bolt and attaching bolt. The limiting failure mode was determined to be bolt shear. The maximum shear failure load was 145,400 lbf.

This failure load equates to be approximately 600% higher than the allowable load determined in accordance with the 2015 International Building Code and Chapter 17 of ACI-318.

You can see the full boltable concrete embed plate structural load qualification test in the video below!

Interested in learning more about how EM-BOLT boltable embed plates save construction costs and time? Take advantage of the Guide below!

Would you like help with your concrete embedded plate engineering calculations? Reach out to us below.

Embedded plate Revit drawings of our standard series of products are also available, for Revit drawings go here.

To learn more about the advantages of EM-BOLT Boltable Embedded Plates, go here.

To learn more about our Concrete Slab Thermal Break solutions, go here.