Why weld when you can bolt?

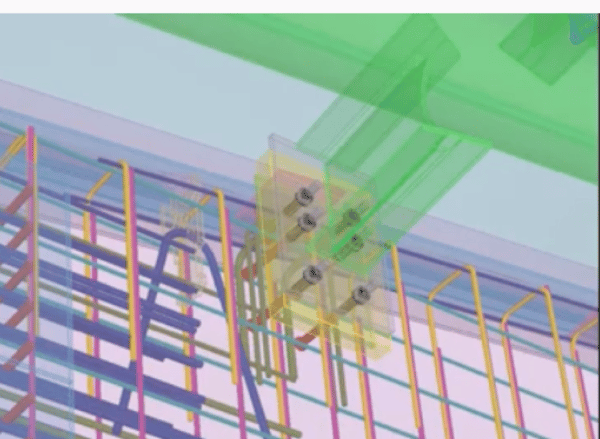

With this new patented boltable embed steel plate design:

In addition to the recognized purchase and install cost savings, EM-BOLT steel embed plates reduce on-site construction risks.

Onsite welding risks are eliminated:

Ready to learn more about our innovative money saving structural steel erection solutions?

(802) 448-3053

EM-BOLT steel embed plates also provide structural engineering design advantages over traditional steel embed plates.

Structural Advantages:

Here are design examples to ACI 318-14, Chapter 17:

EM-BOLT Embed Plate Design - Using HILTI Profis™ Software Analysis

EM-BOLT Embed Plate Design - Using Simpson Strong-Tie Anchor Designer ™ Software Analysis

Don't worry about the design details!

For an example of a complex project with custom embed plates and innovative thermal break technology, read our article on the Institute for Advanced Study at The Rubenstein Commons on the Princeton University campus.

By freeing your welding resources to perform other valuable work, boltable embed plates can be installed and structural beams connected with common construction labor.

Go here to see how installation is fast and efficient.

Don't take our word for it, see a case study here!

See a standard welded embed plate vs boltable concrete embed plate cost savings case study here.

EM-BOLT boltable embeds enable thermal breaks where welded concrete embed anchors do not.

Meet demanding building energy efficiency goals and codes regarding concrete thermal breaks with new thermal break technology.

Stay tuned! EM-BOLT is launching new thermal break structural steel joining solutions shortly including the concrete slab embeds to replace concrete embed angles used for concrete slabs which create a thermal bridge to building exteriors.

Interested in seeing exactly how EM-BOLT boltable solutions will save you money on your structural steel products? Get the Guide below!

Learn how using the EM-BOLT boltable embedded plate technology in the connection between steel and concrete reduces construction costs & timeline risks, while improving structural performance and energy efficiency!

"Embolt provided a unique product that met our needs and exceeded our expectations.

EM-BOLT’s flexibility and creative approach to handling the relentless design challenges of this project was critical to our success."

Virtual Design & Construction Manager

Matt Wert, CM-BIM W.S. Cumby, Inc.

“The speed and efficiency of installing EM-BOLT in the formwork greatly reduces the field labor compared to field welded embed plates, which allows us to stay on schedule with large commercial projects.”

Field Operations Manager

Shawn Robtoy S.D. Ireland Concrete