The EM-BOLT boltable embedded plate design follows many of the installation steps of the traditional welded embedded plate design, making on-site installation easy with little difference to skilled labor.

The key difference comes after the concrete pour. The EM-BOLT boltable embedded plate provides fast and easy assembly to beams that are joined to concrete foundations. By freeing welding resources on site to be used where they are more valuable, concrete embedded plate to beam joints can be made with AISC standardized bolted connections. This saves time and money on every project as well as reducing risk.

Welded Embedded Plate vs Boltable Embedded Plate

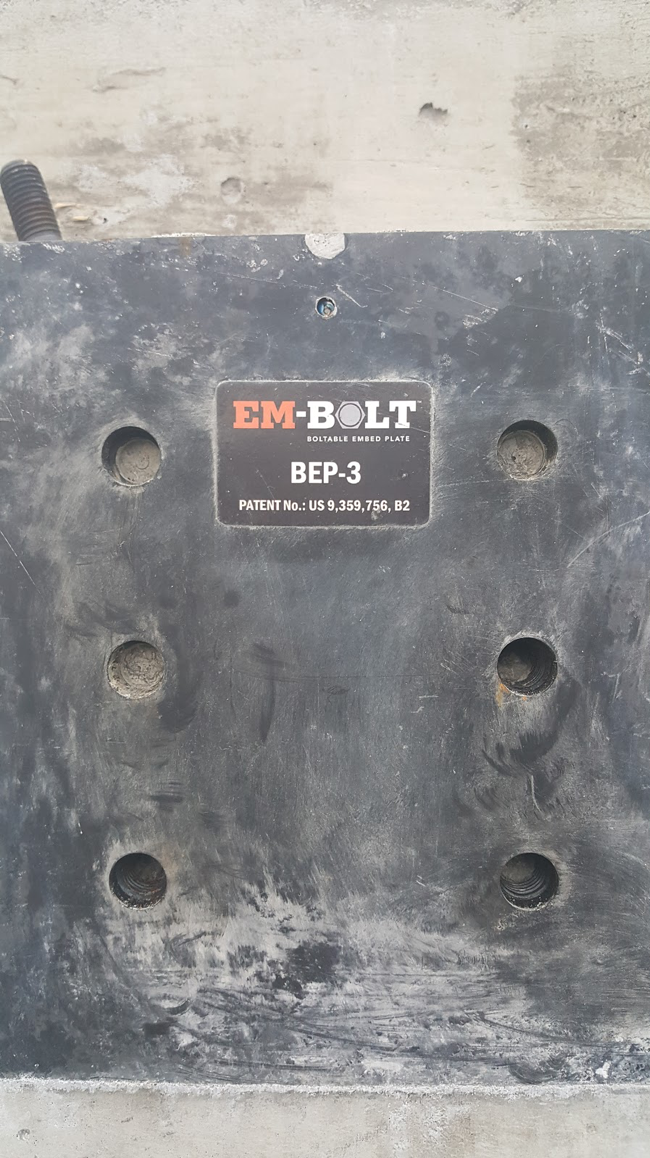

Here are the details of the EM-Bolt boltable embedded plate installation.

Embedded Plate Installation Detail 1:

The EM-BOLT boltable embedded plate design is installed inside the concrete form as would be a traditional embedded plate. A chalk line is snapped on the form indicating top of plate elevation and the plates are aligned to this line.

Concrete Embedded Plate Example

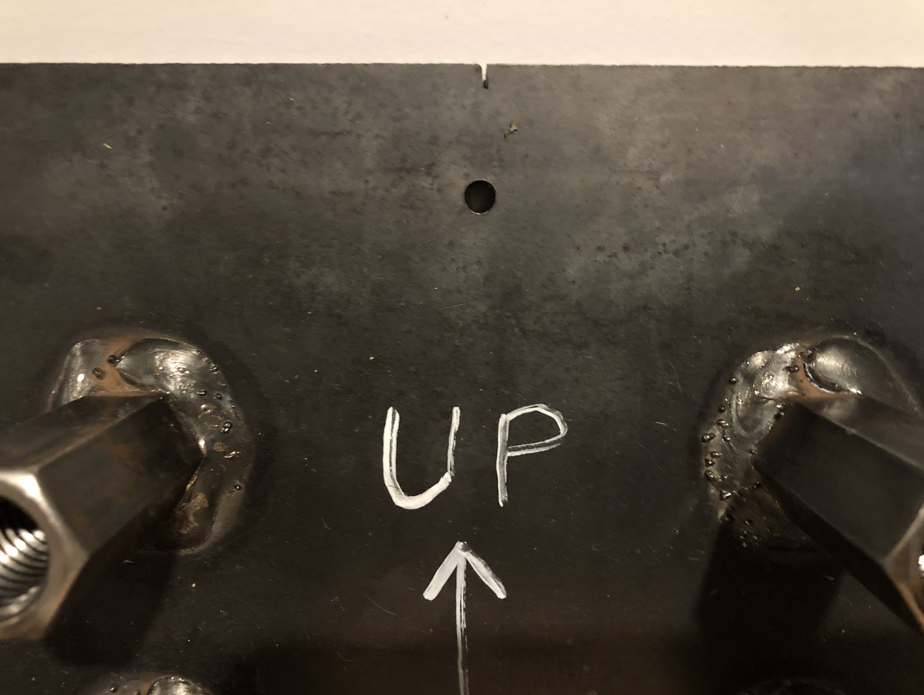

Embedded Plate Installation Detail 2:

The EM-BOLT embedded plate is provided with a centerline slot at the top of each plate. This is for horizontal location. Clip angles for the embedded plate to structural steel joint will have horizontal slots in both legs to allow for movement in both directions due to minor mis-alignment of plates in concrete.

In a typical design, ¾” bolts are used and the slots would be 1 7/8" long, so the clip angle can move 1/2" each way off center. This means that each EM-Bolt embedded plate needs to be within 1/2" either way of center.

Occasionally an embedded plate is positioned outside of this tolerance. If so, the clip angles can be fabricated to align with the installed position of the embed plate.

Embedded Plate Close-up

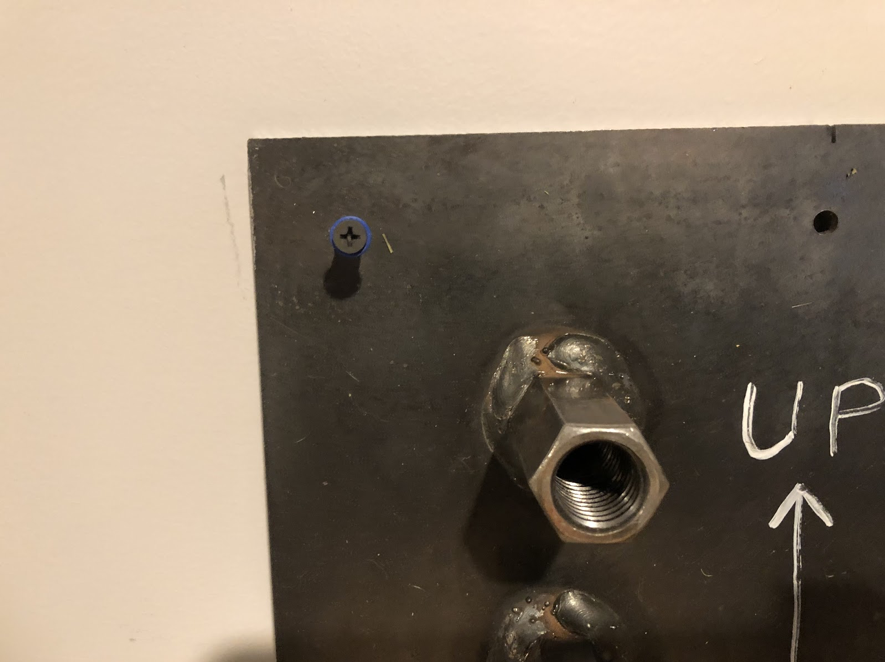

Embedded Plate Installation Detail 3:

The EM-BOLT embedded plate is fitted with decking screws at all (4) corners. This makes installation possible with one person. This person can hold the plate in place and drive the screw in without a helper.

Drywall Screws Provided Ease Embedded Plate Installation

Embedded Plate Installation Detail 4:

Here’s what an EM-BOLT embedded plate looks like in place. You’ll note that the plate is slid into place between the form and the rebar. Bolts provided as part of the EM-BOLT assembly are then added.

Installation - Embedded Plate Detail

Embedded Plate Installation Detail 5:

The bolts are added as shown below and are hand tightened until snug.

Embedded Plate Design - Provides Ease of Installation

Embedded Plate Installation Detail 6:

Occasionally, across a large number of embedded plate installations, a bolt installation or two is missed. As in the picture below, as soon as the plastic protective cap is removed, it’s easy to see that the concrete is visible.

If this is the case, the concrete is drilled out through the existing hole in the embedded plate and the location where the bolt would have been is replaced with an adhesive anchor.

Installation Detail of Embedded Plate

Embedded Plate Installation Detail 7:

The difference between the EM-BOLT boltable embedded plate and a standard welded plate is that the embedded plate to structural steel joint is bolted as shown below, rather than welded. This saves significant project costs.

Concrete Embedded Steel Plate to Structural Steel Joint

Embedded Plate Installation Detail 8:

In addition to being easy to install, the EM-BOLT boltable embedded plate is a more reliable connection and can be easily designed into any project.

To learn more about the advantages of the EM-BOLT Boltable embedded plate, get the eBook below!

For more information on embedded plate design details see our articles:

EM-BOLT Embed Plate Design - Using HILTI Profis™ Software Analysis

EM-BOLT Embed Plate Design - Using Simpson Strong-Tie Anchor Designer ™ Software Analysis

Interested in learning more about how EM-BOLT boltable embed plates save construction costs and time? Take advantage of the Guide below!

Would you like help with your concrete embedded plate engineering calculations? Reach out to us below.

Embedded plate Revit drawings of our standard series of products are also available, for Revit drawings go here.

To learn more about the advantages of EM-BOLT Boltable Embedded Plates, go here.

To learn more about our Concrete Slab Thermal Break solutions, go here.