The commercial building industry is investing significantly in improving building energy efficiency to comply with new energy codes and standards including ASHRAE 90.1, NECB, IECC, LEED and other Green Building Programs.

ASHRAE Standard 90.1, the Energy Standard for Buildings Except Low-Rise Residential Buildings (ref. 1) (included by reference in the International Energy Conservation Code (ref. 2)) addresses thermal bridging in wall, floor and roof assemblies by mandating that thermal bridging must be accounted for when determining or reporting assembly R-values and U- factors.

Commercial building insulation systems have markedly improved as a result of these codes and standards, resulting in commercial building envelopes being more energy efficient than ever.

The focus is now turning to areas of the building envelope where thermal bridging occurs. Thermal bridging is the effect that occurs when a highly thermally conductive material such as steel or concrete creates a ‘bridge’ to conduct heat through the wall insulation system and into (in the case of air conditioned buildings), or out of (in the case of heated buildings), the building envelope.

Despite Advances in Building Thermal Envelopes - There Are Still Thermal Bridging Issues

Areas of concern that can be challenging to solve for thermal bridging include window frames, elevated concrete slab edges and exterior design elements such as canopies and balconies. A new thermal break material introduced below solves many of these difficult to address thermal bridging design areas. However, a particularly difficult thermal bridge to address is the concrete slab-on-deck edge that is produced when a concrete slab floor is joined to the concrete foundation in structural steel buildings. A novel solution to address this joint is introduced further below.

Concrete slab edges are of particular concern because of the surface areas and geometries involved which make them ideal thermal bridges.

Concrete slab edges can create a thermal bridge around the entire periphery of the building on every, or nearly every floor. Concrete slab floors also can be quite thick, meaning that the exterior area of the concrete edges conducting heat to or from the external air can be large as well. Additionally, internal to the building, the area of the floor system means that there can be ample area to conduct heat into or out of the floor system itself.

This means that concrete slab floor edges remain a significant source of building energy inefficiency, with some estimates of energy loss being as high as 50% of the energy loss of a commercial building.

Not only are uninsulated concrete slab edges a source of costly energy loss and non-compliance with building codes and a missed opportunity for a higher green building certification, but they can also affect far more than the cost of operating the building.

Cold concrete slab floors create occupant discomfort by creating uncomfortable cold surfaces and building cold spots. Commercial Building HVAC systems become difficult to balance as localized cold spots need to be managed across multiple seasons, leading to hot areas and cold areas, further increasing energy consumption as occupants try to find the elusive ‘sweet spot’ for comfort. Commercial buildings that aren’t as well insulated as they can be, generate unresolvable occupant complaints and can cost owners money.

Modern commercial buildings are air tight, being wrapped in airtight vapor barriers. This means that the humidity from the building operation and human off-gassing can reach levels of 35% to 50% during winter. While higher internal humidity can improve energy efficiency for the building heating system (humid air conducts heat better than dry air) and increase occupant comfort, unfortunately higher internal humidity levels also can allow the interior to reach the dew point in colder areas. Condensation can form and can lead to unsightly stains, internal material damage and worst of all, harmful interior mold.

Interior Mold Due to Thermal Bridging of Concrete Slab - Courtesy Facilities Management Advisor

Interior mold may not be immediately apparent like in the picture above. Mold can grow on the interiors of wall surfaces such as the inside face of sheetrock, on interior studs and in interior insulation. Hidden mold can accumulate for years before it becomes visible or is identified as a cause of an unhealthy building. Interior mold can at minimum reduce building value due to lower rents and occupant turnover. At worst interior mold can cause respiratory ailments, necessitate expensive remediation and create expensive lawsuits.

Potential Issues Created by Concrete Slab Edge Thermal Bridging:

- Surprisingly high building energy loss

- Lack of building compliance and lower than necessary LEED Ratings

- Unanticipated structural expansion and contraction

- Exterior ice buildup and resulting damage from ice dams or hazard on building exterior due to snow melt and refreezing

- Uncomfortable internal surfaces

- Difficult to balance HVAC systems - building hot and cold areas

- Internal condensation - building damage and mold health hazard

Concrete-to-Concrete Slab Edge Thermal Break Technology

Companies like Armatherm™ are developing innovative structural steel thermal break products that enable architects and structural engineers to design thermal breaks to reduce thermal bridging in window frames, balconies and other tough to insulate structural steel building areas.

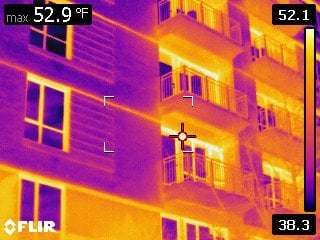

The thermal images below show the massive potential for heat loss from buildings due to thermal bridging of structural steel through the building insulation envelope. In the case below the balcony features allow a direct conduit of heat to the outside of the building via the balcony and canopy structural steel connections. (Purple is cooler and yellow to red is warmer)

The exposed concrete architectural detail above traditionally has been hard to insulate

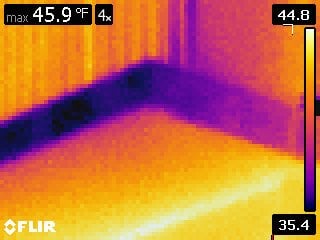

In addition to the cost of the energy loss to the exterior, the resulting cool areas inside the building as shown below (purple) are the direct result of lack of insulation of the structural steel connections and can lead to the condensation and mold conditions discussed earlier.

The resulting heat loss from thermal bridging through the structural steel to exterior conduit

The resulting heat loss from thermal bridging through the structural steel to exterior conduit

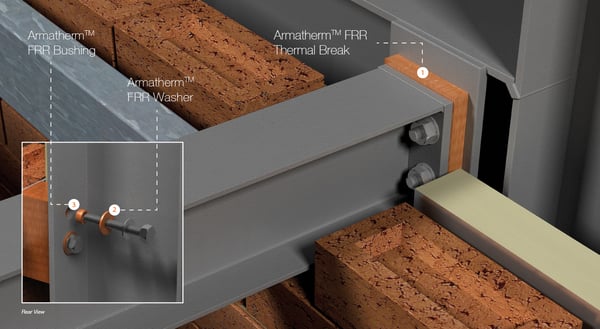

Armatherm has developed innovative thermal break materials that enable bolted structural steel connections to be insulated, eliminating the structural steel thermal bridge and radically reducing heat loss from the building and the interior cold areas that can cause discomfort and health hazards.

Example of Armatherm Thermal Break Material for Structural Steel Balcony Canopy - Courtesy Armatherm

Example of Armatherm Thermal Break Material for Structural Steel Balcony Canopy - Courtesy Armatherm

New Thermal Break Concrete Slab-on-Deck Solution

Until now, there hasn’t been a thermal break solution for the concrete slab-on-deck to concrete foundation connection.

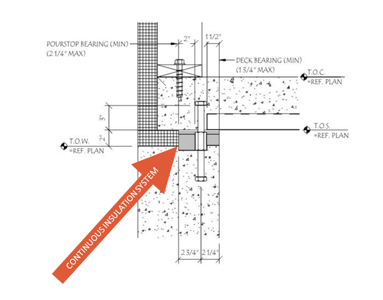

Our concrete slab-to-concrete foundation slab edge insulation system provides a method to reliably transfer structural loads from the concrete slab to the concrete foundation while introducing a structurally resilient thermal break insulation layer which dramatically reduces thermal bridging from the conditioned floor to the unconditioned foundation.

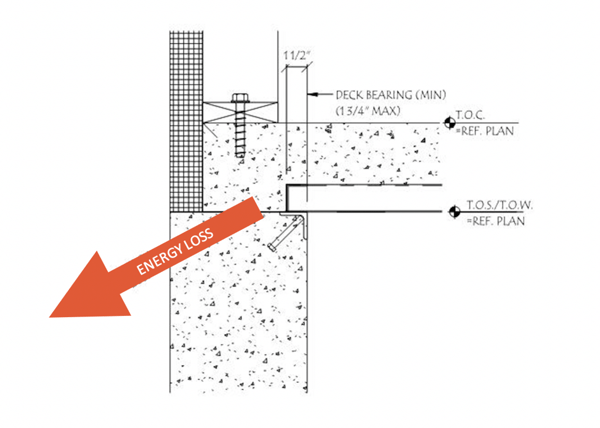

In a traditional concrete slab edge, a significant thermal bridge is created which results in energy loss that contributes to the consequences noted above.

Energy Loss From Lack of Raised Concrete Slab Edge Insulation

Energy Loss From Lack of Raised Concrete Slab Edge Insulation

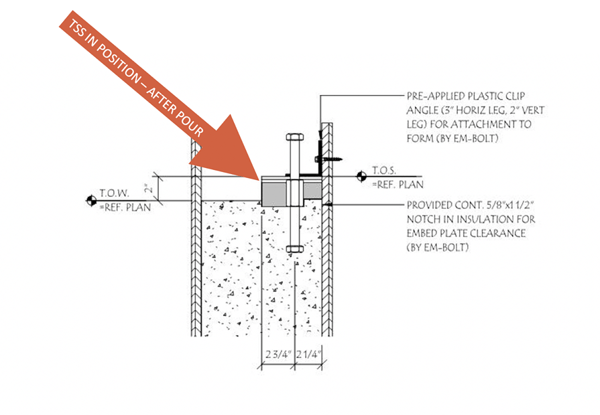

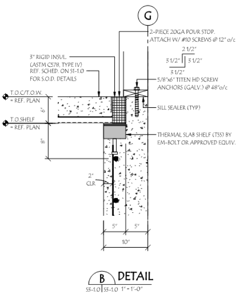

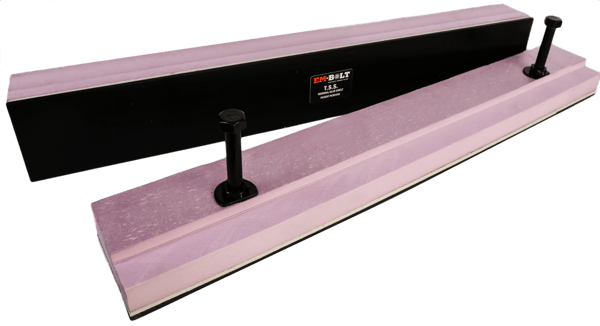

The EM-BOLT TSS (Thermal Slab Shelf) system provides a structural bridge with an innovative concrete anchoring system that passes structural loads from the concrete slab floor to the foundation while inserting a thermal break layer.

Detail of Thermal Slab Shelf (TSS) Thermal Break Concrete Slab Solution

Detail of Thermal Slab Shelf (TSS) Thermal Break Concrete Slab Solution

The as-poured thermal break system is shown below.

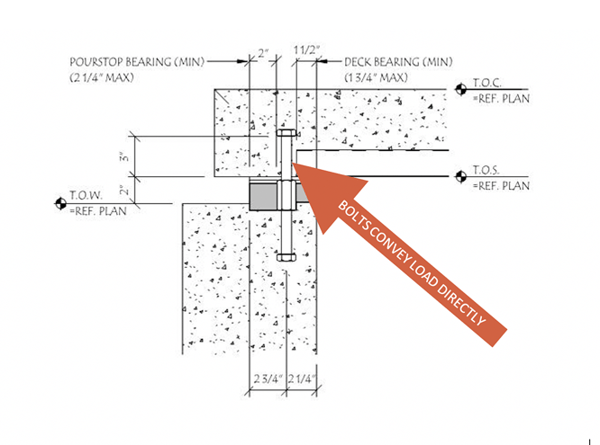

Detail of TSS Thermal Break Concrete Slab Solution - Showing Structural Load Bearing Anchor Design

Detail of TSS Thermal Break Concrete Slab Solution - Showing Structural Load Bearing Anchor Design

The TSS system easily adapts to multiple concrete slab-to-foundation wall design configurations while providing an effective thermal break concrete slab solution.

![]()

TSS Shelf Options - Showing Complete Contiguous Thermal Break Concrete Slab Solution

TSS Thermal Slab Shelf

TSS Thermal Slab Shelf

In Addition to the TSS System We Also Provide Innovative Boltable Embed Plates

The structural thermal break materials from Armatherm are ideal for structural steel-to-steel connections that are bolted. However, typical concrete embed plates are welded to the structural steel beams that support the slab-on-deck floor of structural steel buildings.

The patented EM-BOLT boltable embed plate eliminates the structural steel weld at the concrete to steel connection and replaces it with a bolted connection, allowing for the integration of thermal break materials to insulate this connection.

Traditional concrete embed plates are welded to the structural steel beam of the floor. EM-BOLT embed plates are bolted to the concrete

Freeing your welding resource to perform other more valuable on-site welding is proven to save construction project costs and reduce construction timelines.

EM-BOLT boltable embed plate with Armatherm Thermal Break Material

EM-BOLT boltable embed plate with Armatherm Thermal Break Material

Steel-to-Concrete Connection Thermal Break - See the Cost Savings Case Study Here

Steel-to-Concrete Connection Thermal Break - See the Cost Savings Case Study Here

Summary

The TSS system, installed as shown below, partners well with the EM-BOLT boltable embed plate with thermal break technology shown below that. These solutions reduce building construction cost and timelines while radically improved building envelope energy efficiency.

TSS Thermal Break Concrete Slab Solution in Place above EM-BOLT Boltable Embed Plate with Thermal Break Technology

TSS Thermal Break Concrete Slab Solution in Place above EM-BOLT Boltable Embed Plate with Thermal Break Technology

EM-BOLT is delivering innovative commercial building thermal break solutions including new solutions for managing the thermal bridging of elevated concrete slabs.

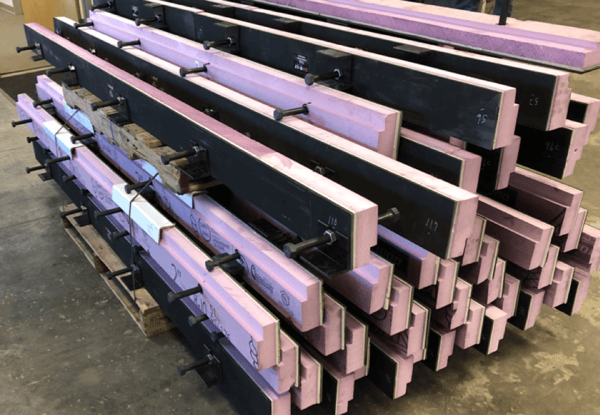

EM-BOLT is able to provide TSS systems to meet your next project’s needs.

TSS Thermal Slab Shelf Order Ready for Delivery to Jobsite!

TSS Thermal Slab Shelf Order Ready for Delivery to Jobsite!

Interested in learning more about how EM-BOLT boltable embed plates save construction costs and time? Take advantage of the Guide below!

Would you like help with your concrete embed plate engineering calculations? Reach out to us below.

Embed plate Revit drawings of our standard series of products are also available; for Revit drawings go here.

To learn more about the advantages of EM-BOLT Boltable Embed Plates, go here.

To learn more about our Concrete Slab Thermal Break solutions, go here.