Eagles Landing Mixed Use Building

Eagles Landing is a mixed use building built for Champlain College in Burlington, VT. It includes housing for 314 students as well as retail stores. The building achieved Two Green Globes certified by The Green Building Initiative (www.thegbi.org).

In order to achieve the Green Globe awards, energy efficiency of the building envelope was a priority. That’s why replacing standard weld plates with thermal break embeds was important!

Example - Embed Plate with Thermal Break Technology Replaces Standard Weld Plate Design

However, just as important, as with every structural steel project and building, is to get the project completed on time and on or under budget. That’s where the patented EM-BOLT boltable embed plate outshines standard weld plate designs.

Eagles Landing Structural Steel Framework

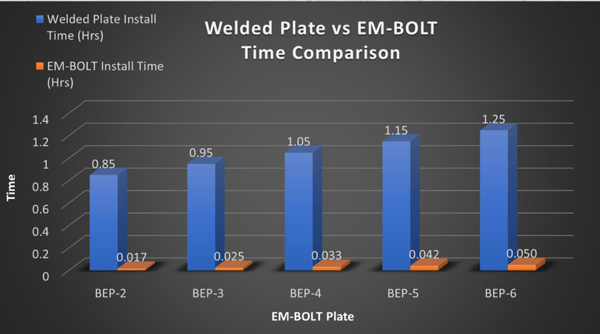

The boltable EM-BOLT embed plate saves considerable installation time vs the standard steel weld plate configuration. Contractors report 80-100 man-hours saved on average-size commercial projects. This time savings can translate into 2 - 3 weeks of compressed construction schedule.

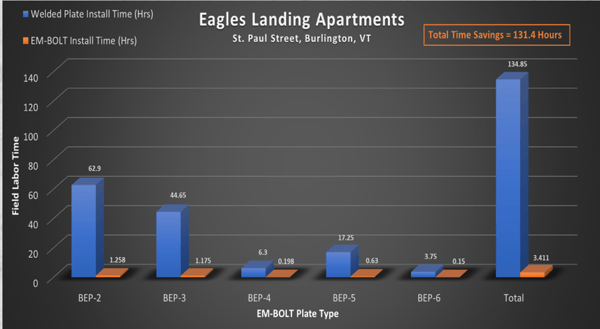

Reported Time Comparison - Standard Weld Plate vs. EM-BOLT Boltable Embed Plate

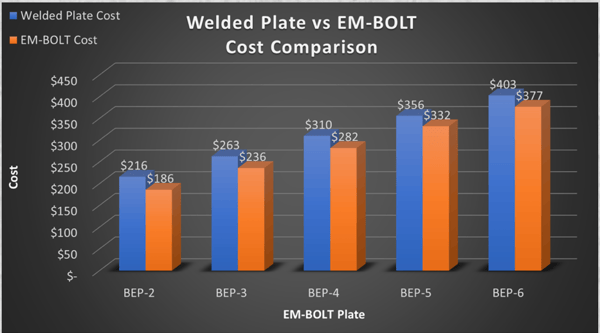

On this project, the procurement costs of the boltable embed plate were less than the standard weld plate design quoted.

Contractor Procurement Cost Comparison - Standard Weld Plate Vs. EM-BOLT Boltable Embed Plate

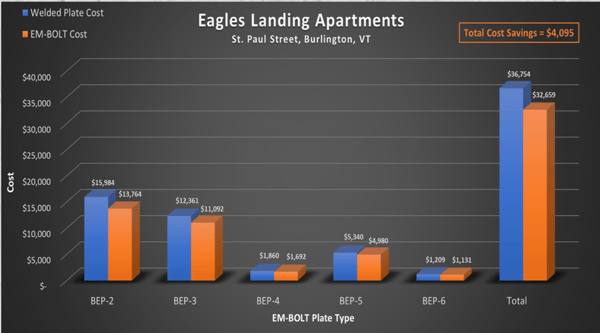

Across the Eagles Landing project, 288 EM-BOLT boltable embed plates replaced traditional weld plates for the approximately 30,000 SF structure.

For the project as a whole, the results are impressive:

- Time savings on Eagles Landing = 131 Hrs

- Cost savings on Eagles Landing = $4,095

Cost by Weld Plate Size - Weld Plate vs.

Boltable Embed Plate and Total Costs for Each Weld Plate Type

Labor Savings by Weld Plate Size vs. Boltable Embed Plates and Total Project Labor Savings

Learn about how our proprietary Concrete Slab Thermal Break solutions solve many common thermal break challenges for architects and structural design engineers while meeting demanding energy codes today.

The patented EM-BOLT boltable weld plate frees your welding resources to do more valuable work.

“The speed and efficiency of installing EM-BOLT embed plates in the formwork greatly reduces the field labor compared to field welded weld plates, which allows us to stay on schedule with large commercial projects.”

Shawn Robtoy

Field Operations Manager

In addition to the recognized purchase and install cost savings, the EM-BOLT embed plate reduces on-site construction risks.

- Onsite welding risks are eliminated

- Welding fumes and flash are minimized

- Risks associated with ladders in the elements are minimized

- All welding is done in a controlled environment – quality is not compromised by inclement weather

EM-BOLT steel embed plates also provide structural engineering design advantages over traditional weld plates.

- Structural Advantages

- EM-BOLT offers direct load transfer to each anchor bolt – no localized stresses in plate

- More consistent connection – not relying on quality of weld

- Full-scale load tested to sustains a working load of almost 600% of the maximum load required by the 2015 International Building Code and Appendix D of ACI-318.

Interested in learning more about how EM-BOLT boltable embed plates save construction costs and time vs. weld plates? Take advantage of the Guide below!

Would you like help with your concrete embed plate engineering calculations? Reach out to us below.

Embedded plate Revit drawings of our standard series of products are also available, for Revit drawings go here.

To learn more about the advantages of EM-BOLT Boltable Embed Plates, go here.