Tilt-up construction (sometimes called tilt-slab construction, tilt-up concrete construction or tilt-wall construction) is the process of using tilt-up concrete walls for the main building structure, usually of a commercial building. Tilt-up construction has many advantages for certain types of building projects and in fact some estimates are that over 650 million square feet of tilt-up construction buildings are constructed in the US in a year!

Example of a Tilt-up Construction Jobsite - Courtesy the Tilt-up Concrete Association

Example of a Tilt-up Construction Jobsite - Courtesy the Tilt-up Concrete Association

In this article we review the basics of tilt-up construction and introduce a new technology to reduce tilt-up construction costs and compress tilt-up construction timelines.

What is Tilt-Up Construction?

Tilt-up construction describes a building construction method where frames are built on the job site in order to pour concrete wall panels on the ground, much like you would form a poured slab foundation. In this case however, provisions are taken to enable the poured concrete slab to then be ‘tilted up’ to turn this slab into a concrete wall. These concrete walls usually form the exterior of the building and are the main building structure, in lieu of other types of walls and building structures such as fabricated structural steel.

The walls are poured at the job site, typically using dimensional lumber forms, rebar and concrete. Additional materials may be applied or constructed into the wall as it’s crafted while laying on the ground including brick fascias, insulating materials, any coatings, wall lifting points and concrete-to-steel connection points such as embed plates. The forms enable the wall to be formed with key architectural details in place, such as windows and doors.

When the walls have cured in the forms on the ground, they are tilted up, usually using a crane as they can be quite large and heavy. The tilt-up walls are then moved into position and set on foundation footings. Each panel is braced after it’s moved into position until the walls are tied together to create a freestanding structure.

Tilt-up Construction Wall Placement - Courtesy the Tilt-up Concrete Association

Tilt-up Construction Wall Placement - Courtesy the Tilt-up Concrete Association

If you’ve ever been around a home or small building construction site, you’ve probably seen the essence of ‘tilt-up construction’ where a studded wall is constructed laying flat on the floor and then a handful of workers tilt it up and hold it while it’s nailed into position. While the mechanics are somewhat the same, ‘tilt-up construction’ in professional circles usually refers to the poured concrete method described above.

You’re surrounded by tilt-up construction buildings! Any building that is relatively low-rise, that need only support a roof and that often has a large, open internal space is potentially an ideal candidate for tilt-up construction.

Typical Tilt-up Construction Project - Courtesy the Tilt-up Concrete Association

Typical Tilt-up Construction Project - Courtesy the Tilt-up Concrete Association

Many large retail environments and membership-based stores, warehouses and distribution centers use tilt-up construction walls with internal steel columns to support a roof that spans a very large square foot interior.

This video below walks through all of the key elements to understand Tilt-up Construction methods - courtesy Civil Engineering.

Tilt-up Construction Frame from Video Above Showing All of the Embed Plates

Planning for Tilt-up Construction

Tilt-Up construction requires forethought to ensure that the as-cast wall panels accurately reflect the design goals of the building. Contractors also must be adept at thinking through the construction site to prepare for pouring the panels. Pouring tilt-up construction wall panels requires a level, flat and smooth surface large enough for each of the wall panels to be created on. This may be the poured slab of the building itself or this may require a temporary slab or surface suitable for forming the walls while the project is ongoing.

Releasing agents of some type are used to ensure that the wall to be tilted up doesn’t adhere to the surface it’s being formed on and special care is taken when applying release agents or surface materials such as facias to ensure wall integrity isn’t impacted when the wall is tilted-up.

Advantages of Tilt-up Construction

Tilt-up Construction, in the right applications, can be incredibly cost-effective.

For high-rise buildings, there’s a need for a structural steel framework to carry the building design loads. However, for buildings that are not as tall, and that maybe only need to carry a roof and resulting roof loads, it’s possible to design a structure that doesn’t require a structural steel frame. This can save considerable cost from the reduction in structural engineering costs through to the acquisition and fabrication of a structural steel frame system.

Locally sourced ready-mix concrete, rebar and dimensional lumber is usually more readily available than having steel beams or complex building parts fabricated and shipped to site.

Because of the ability to create a large amount of square footage under a relatively low roof, tilt-up construction often becomes more and more attractive the larger the square footage of the building being planned.

Tilt-up Construction can have the advantage of speed.

Walls might take a few days on site to cure, but this is still less time than a structural steel project would usually take and because the wall / structural system can be up faster, the roof can be in place faster and construction can move inside more quickly, which will usually accelerate the whole job.

There’s some reduction in construction timeline risk with Tilt-up Construction.

As there are fewer critical path items (such as structural steel beams) to potentially slow things down and the contractor on site has a large degree of control over the pace of wall creation, timeline risk is lessened.

Tilt-up Construction can still be energy efficient.

Reinforced concrete is a better thermal insulator than structural steel, so there can be some energy advantages to tilt-up construction vs. a structural steel framed building, and by applying extra insulation systems, tilt-up construction buildings can be as energy efficient as other types of commercial buildings. Even the steel-to-concrete connection which we'll talk more about below can be thermally broken with our innovative steel-to-concrete joint thermal break technologies.

The difference between Tilt-up Construction and Precast Construction.

Tilt-up construction is often confused with precast construction. The difference is that precast concrete panels are poured in a facility remote from site. Precast construction has some of the same cost and timeline advantages of tilt-up construction, in that an internal steel frame may not be needed, however precast construction is more often used when the panels have complex shapes requiring some advanced concrete forming capabilities or when there's simply not enough room on site to form tilt-up walls. Tilt-up construction is used when the wall geometries are relatively simple.

Tilt-up Construction can still be made more cost-effective, can have even less timeline risk and can be made safer with EM-BOLT!

Even though tilt-up wall construction can be very cost-competitive and responds well as a solution for tight timeline projects, this method can be even further improved!

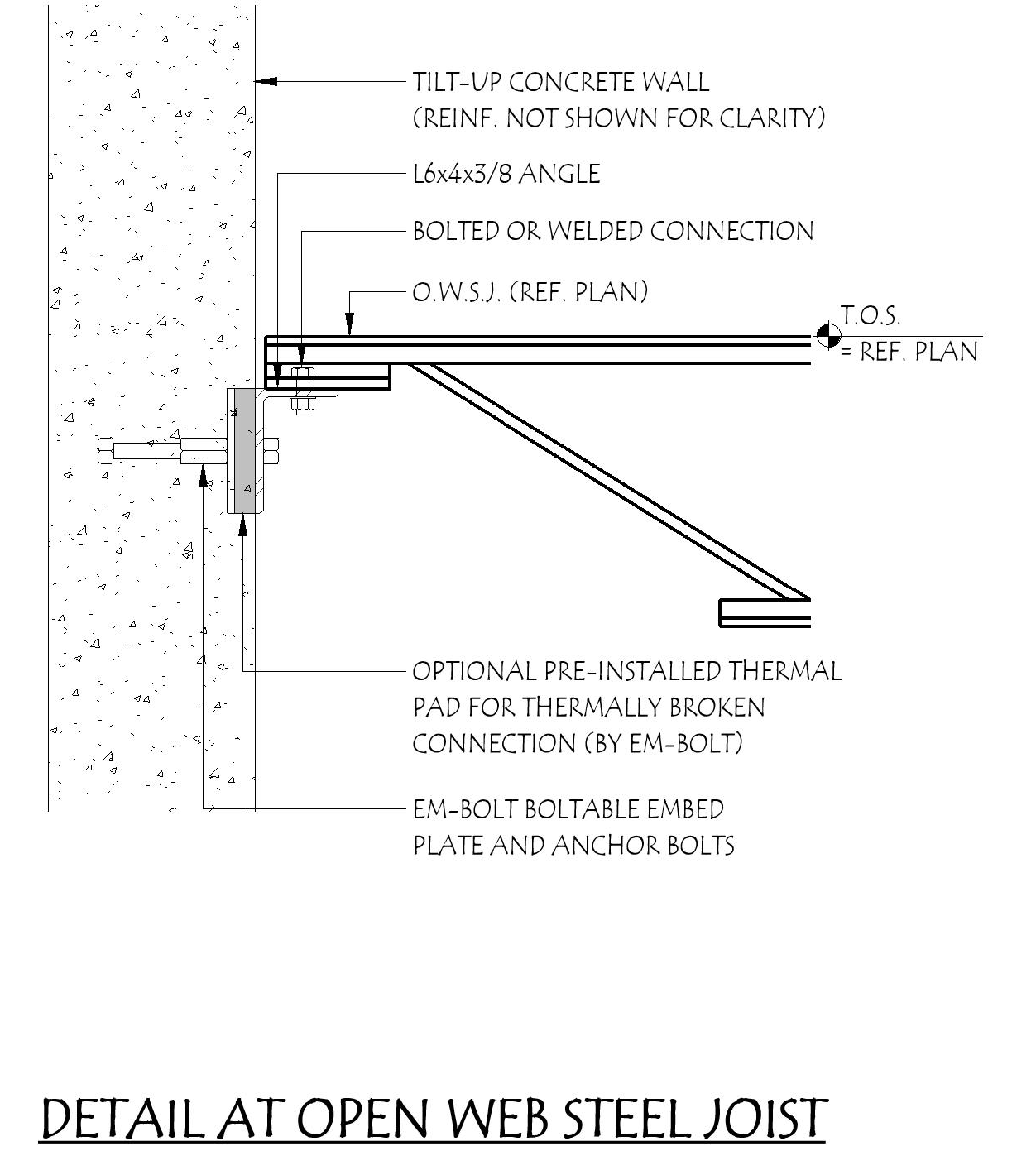

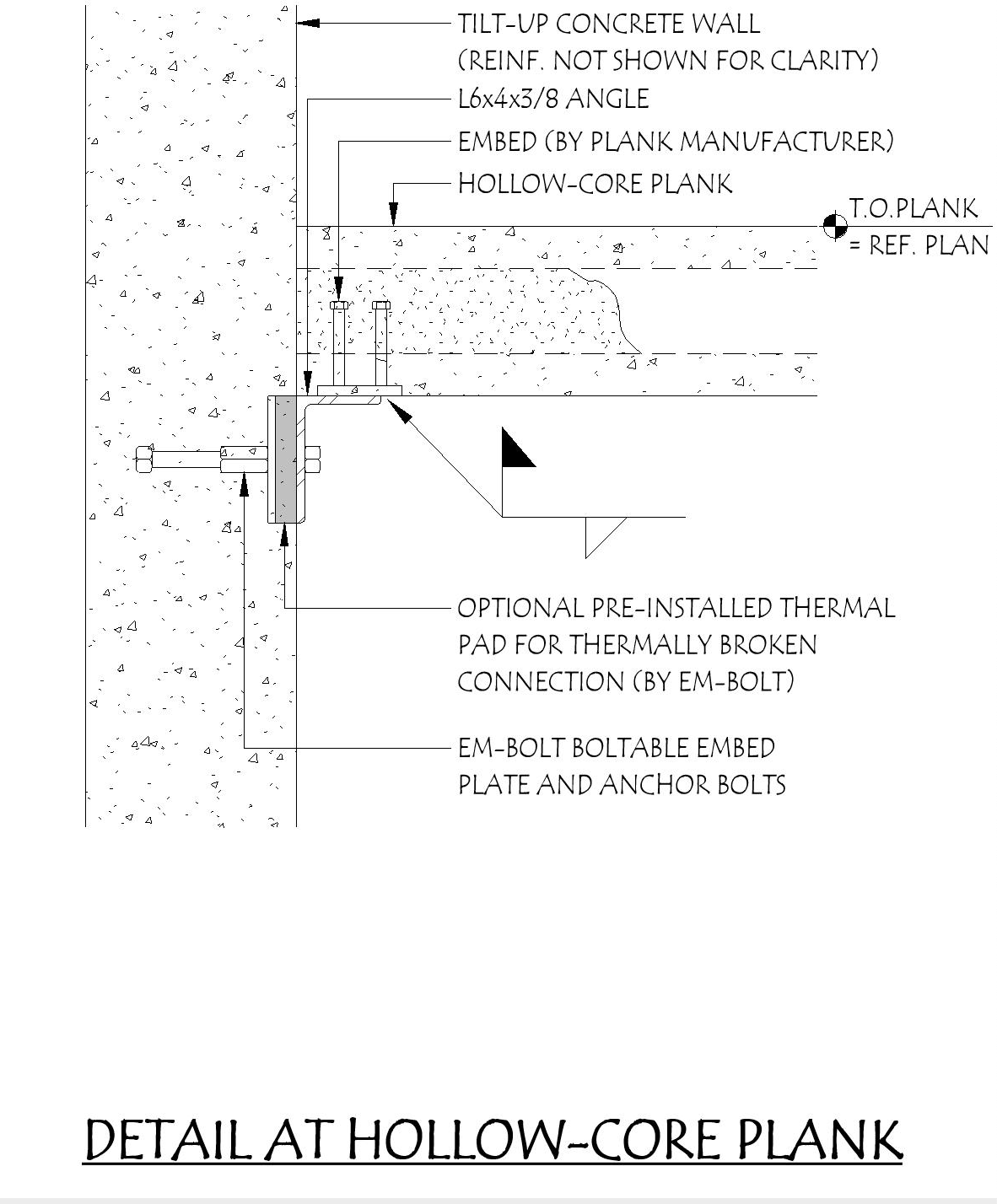

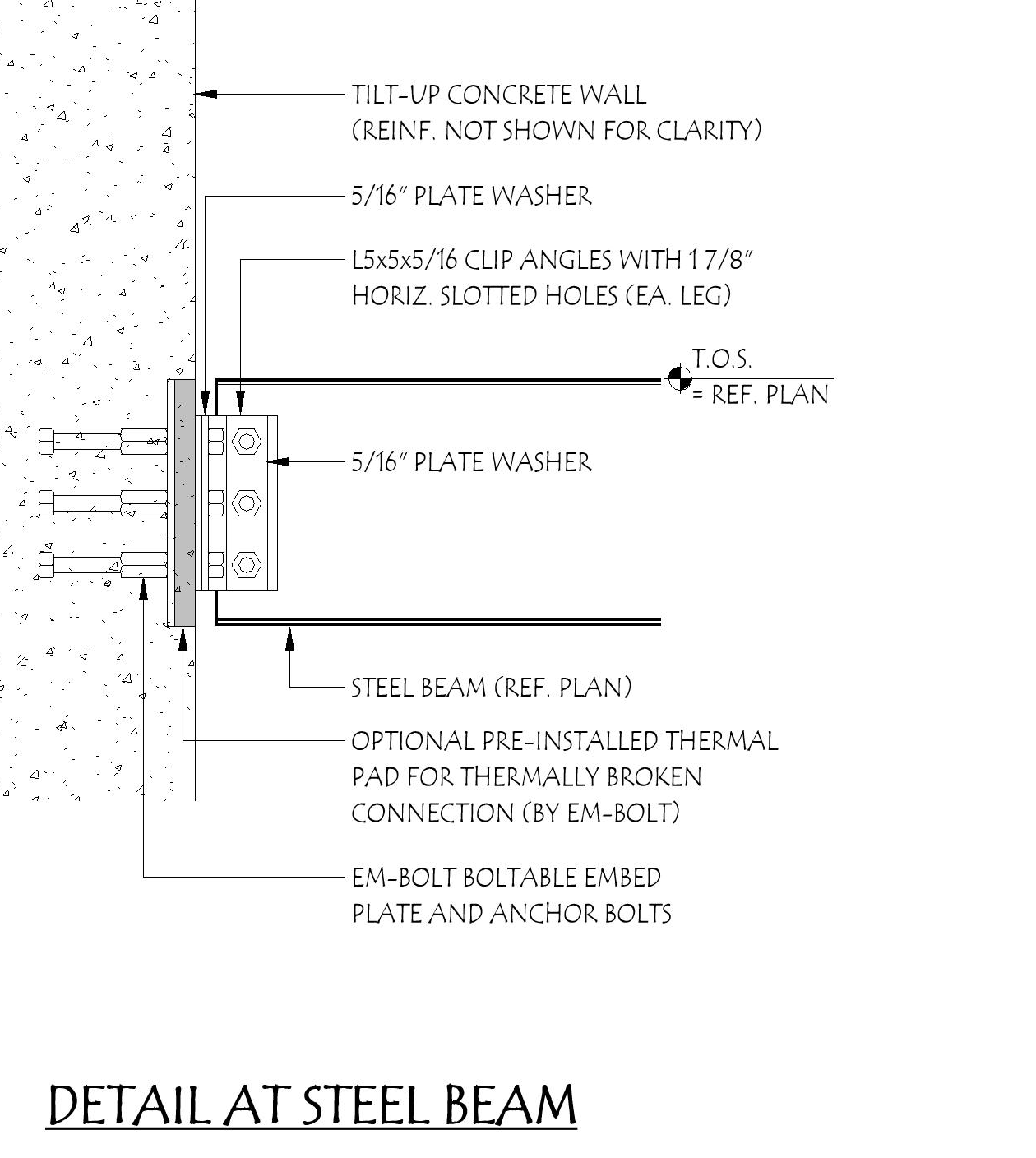

In tilt-up construction, the walls are tilted up and temporarily held in place until some joining system is used to lock them in place. The joining system is usually structural steel beams which span the building, connecting the walls to each other across the floor span and ultimately supporting the roof. The steel-to-concrete connection to create the roof spanning structural system would typically include a welded embed plate.

For tilt-up wall projects however, since there is far less structural steel work involved, there are typically fewer welding resources available on site. This means that for making the steel-to-concrete connection in a typical tilt-up construction project, certified welders and qualified inspectors need to be sourced and brought in just for this one operation - welding the steel embed plate to the structural steel beam and doing the follow-up inspections.

As we’ve been able to demonstrate in structural steel-based construction projects, the steel-to-concrete joint can be made using EM-BOLT patented boltable embed plates, which lowers construction labor costs, frees up welding resources for other more important work, reduces inspection costs and risks and compresses construction timelines. Although all welding cannot be eliminated, using EM-BOLT embed plates can dramatically reduce the amount of welding required for tilt-up construction.

Using EM-BOLT boltable embed plates, which are cast in place just like standard welded embed plates, saves process cycle times for every tilt-up wall panel.

EM-BOLT Boltable Embed Plate

Eliminating welding of the steel beam to the concrete embedded plate and replacing this process with bolting creates numerous advantages specifically for tilt-up construction projects.

Why Weld When You Can Bolt and Save Time and Money?

It's far faster and easier to attach the clip-angles to the plates using bolts vs. welding. This can mean that a wall panel can be lifted sooner, as the clip-angles can be installed faster, without welding resources. In addition, if weather prevents welding then this operation is delayed. Welding requires approved materials to be carefully stored on site and welding creates visual hazards to nearby workers and potential fire hazards which must be managed. EM-BOLT boltable embed plates eliminate these risks and potential delays.

A boltable steel-to-concrete joint can be created using common construction labor, lowering overall project costs and speeding construction.

Welded construction joints require specialized inspection skills and often some percentage of welds need to be inspected at close proximity, further increasing costs as you need to get the inspector physically close to some percentage of the welds. Numerous bolted joint quality systems are available which can be visually inspected at a distance.

Typical Bolted Connection Inspection Method

Since the driving forces for tilt-up construction as a design and construction methodology are often cost and time, it only makes sense to further compress cost and timelines using advanced boltable embed plate technology!

EM-BOLT has boltable embed plate solutions specifically developed to make tilt-up construction projects faster and less expensive.

These solutions minimize welding at the steel-to-concrete connections which speeds jobs up and minimizes job risk.

You can learn more about tilt-up construction at the Tilt-Up Concrete Association.

You can learn more about the EM-BOLT boltable embed plate here.

Ready to learn more about our innovative money saving construction solutions?

Or, get the guide!

When you use EM-BOLT products, we'll do the calculations and detail design work for free!