We're often asked about the differences between installing our patented EM-BOLT boltable steel embeds and installing standard field welded steel embeds.

You can take advantage of the construction efficiencies of boltable steel embeds while maintaining your existing design engineering and structural steel fabrication and erection processes. The boltable steel embeds are largely installed using the same process that you'd use for standard welded steel embeds.

Below are the steps used to install EM-BOLT boltable steel embeds and important things that you should be aware of vs. traditional field welded steel embeds.

The boltable steel embeds are affixed to the interior of the concrete form using screws supplied with each steel embed as shown below. The screws are integrated with the steel embed so that screws do not need to be held in place by hand while driving them in.

The concrete form should have a chalk line snapped at the Top of Plate Elevation as shown in the picture below in order to enable vertical location and alignment of the steel embed.

The design of the EM-BOLT steel embed allows it to be slid into place without it interfering with the rebar.

Steel Embed Installation into Concrete Form

Steel Embed Installation into Concrete Form

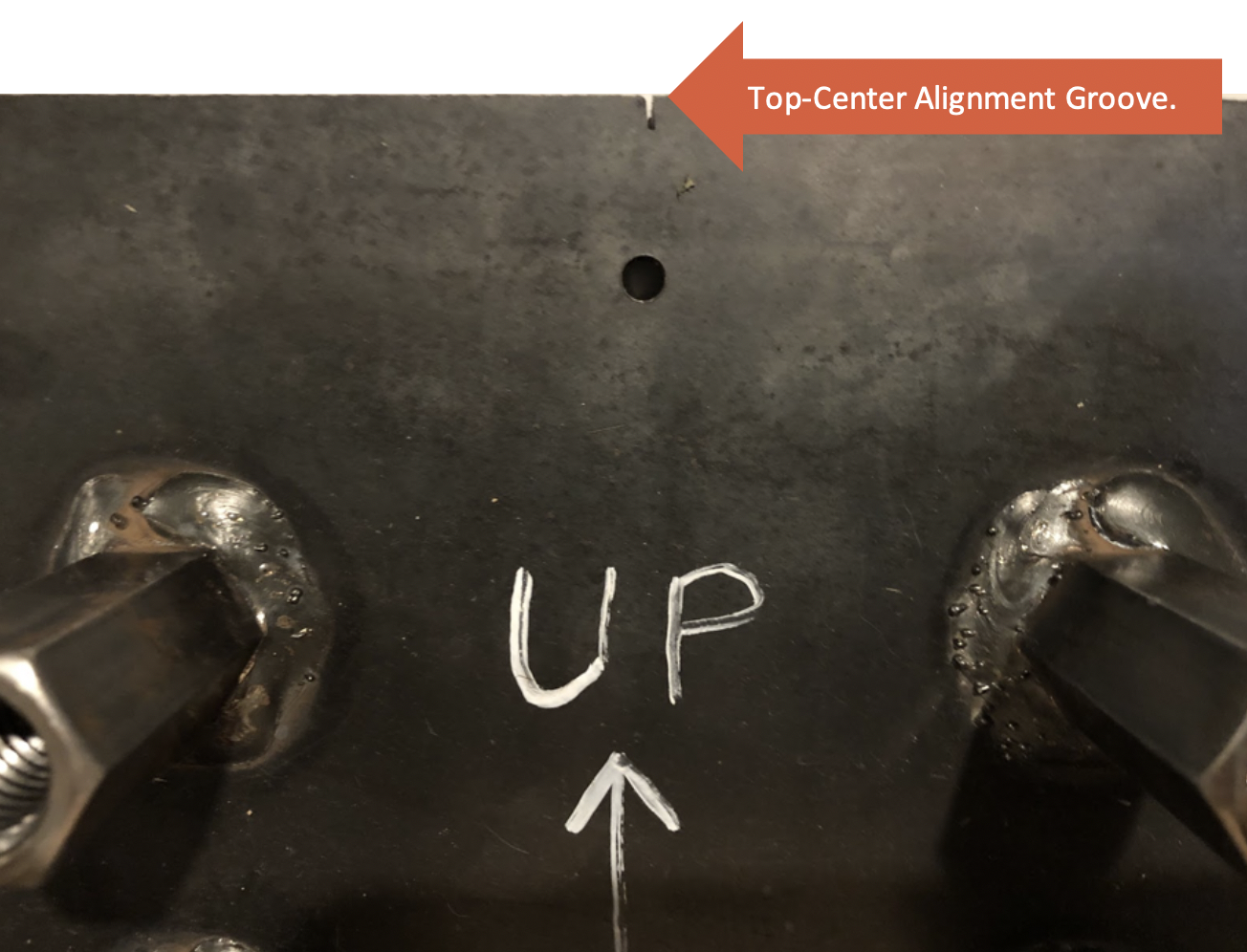

EM-BOLT Boltable steel embeds are provided with a Top-Center alignment groove, shown below, for horizontal alignment. As noted in steps below, there is an allowance of up to 1/2" either way horizontally when fitting up the standard clip angles to the steel embed. In the rare event that a steel embed is off center horizontally more than this allowance, a clip angle with a larger tolerance (longer slots) can quickly be made.

Top Center Alignment of Steel Embed

After the steel embed is slid into place and attached to the inside of the concrete form, bolts are installed into the back of the steel embed by hand until snug. This assembly process (adding the bolts after the steel embed is in place) allows for the embed to be slid into position without interfering with the installed reinforcement (rebar).

Steel Embed to Concrete Connection

Steel Embed to Concrete Connection

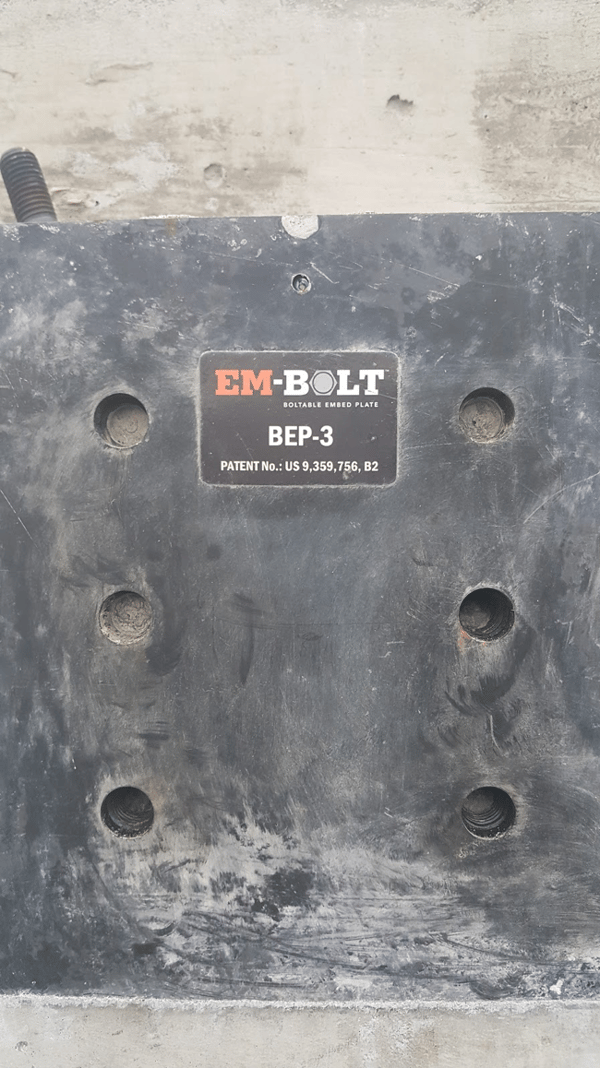

Once the concrete is poured, the concrete form is removed, revealing the steel embed face. The pre-installed plastic thread protection plugs are removed just prior to installing the clip angle.

Steel Embed Face

Steel Embed Face

It's possible, though it has been quite rare, that a bolt is missed in the back of the steel embed prior to the concrete pour. You'll see this as soon as the plastic thread protection plugs are removed. If this happens, simply drill out that location and install an epoxy anchor per the directive of the SER or Project Engineer.

Steel Embed Plate Face with Missing Bolts - Poured to Show as Example

Steel Embed Plate Face with Missing Bolts - Poured to Show as Example

Clip angles are then connected to the steel embeds using bolts. Bolting steel embeds at this stage of structural steel fabrication vs using standard field welded steel embeds saves a significant amount of time and money.

Bolting of the steel to concrete connection as shown below frees welding resources to be applied to other, more valuable tasks. It reduces inspection costs and potential timeline delays from weather or lack of availability of certified welders and inspectors on the right day to meet the project timeline.

Clip Angle Being Bolted to Steel Embed

Clip Angle Being Bolted to Steel Embed

An important design element of our boltable steel embeds is the slots which allow room for adjustment during installation. The steel embed clip angles, as highlighted below, have horizontal slots in both legs to allow for movement in both X and Z horizontal directions. The 1 7/8" long slots are designed for 3/4" bolts, so there is adjustment of up to 1/2" each way off-center horizontally. If a particular steel embed is mis-positioned, a custom clip angle can be quickly fabricated to allow for the additional adjustment needed.

Steel Embed Adjustment Slots

Steel Embed Adjustment Slots

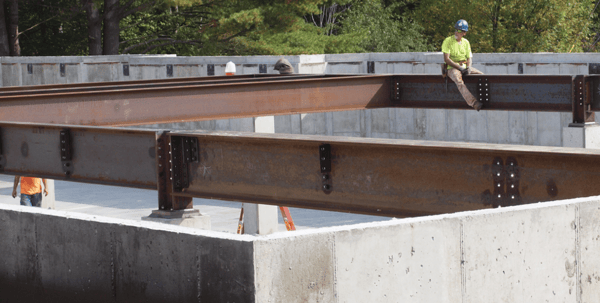

Beams are then lowered into place and bolted as well, again freeing your welding resources to focus where more valuable welding is needed. There is no need for welders being up on ladders, for other workers being exposed to welding hazards and there is less risk of weather delays or delays from certified welders or welding inspectors being unavailable to meet your project timeline.

Steel Embed to Beam Connection

Steel Embed to Beam Connection

The clip angle slots are shown below, allowing for final adjustment in beam placement prior to bolting of the steel to concrete joint.

Steel Embed Clip Angle - Final Steel to Concrete Joint

Steel Embed Clip Angle - Final Steel to Concrete Joint

This is a structural steel project showing the multiple EM-BOLT steel embeds which saved the Owner considerable time and money.

Example of Steel Embeds in Place

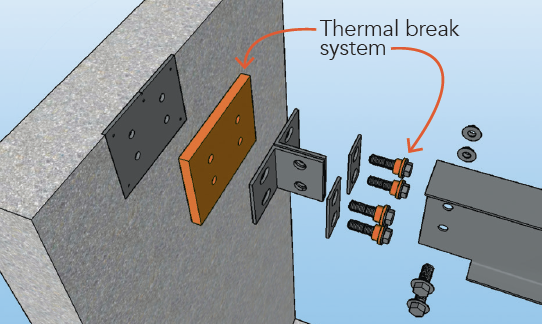

Below is an exploded view of the boltable steel embed assembly components. This particular drawing shows our innovative Thermal Break steel embed solution. This is an easier and industry standard way to integrate thermal breaks into the steel to concrete connection. To learn more about our innovative thermal break solutions, go here.

Steel Embeds Exploded View

Interested in learning more about how EM-BOLT boltable steel embeds save construction costs and time? Take advantage of the Guide below!

Would you like help with your steel embeds engineering calculations? Reach out to us below.

Steel embed plate Revit drawings of our standard series of products are also available, for Revit drawings go here.

To learn more about the advantages of EM-BOLT Boltable Embedded Plates, go here.

To learn more about our Concrete Slab Thermal Break solutions, go here.